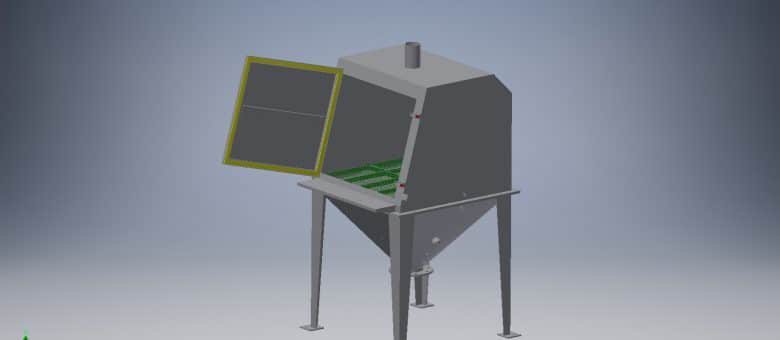

The manual bag unloader is designed for efficient unloading of bags containing powdered products or granules in a clean environment.

Characteristics:

All the parts in contact with the product are in AISI 304 stainless steel and the structural part in painted carbon steel (other materials can be possible).

Functioning:

Place the manual bag discharger in the correct place taking into account that it must be a straight and smooth surface.

Provided with:

- VBS MICRO VIBROFLUIDIFICATION SYSTEM that combines the ventilation of the material at pressures of up to 6 bars with a slight vibration of the hopper wall. Since the working pressure is 2 to 6 bars (29-87 PSI), it is not posible to enter material below the plastic lip, so an additional anti-return valve is not necessary. The compressed air is introduced into the material directly through the silicone lip adhering to the inner wall of the hopper. The instensity of the vibration is regulated with the exercise pressure included between 2 and 6 bars and thanks to the intermittent operation and the maximum duration of 5 seconds, the air consumption is extremely low.

- ROTARY LEVEL OF VIBRATORY PALETTES that allows knowing the presence of material at the height of the assembly through a pivoted measuring blade driven by a synchronous gearmotor. If the content being measured reaches the measuring blade, it is prevented from continuing to rotate since contact closure of the relay occurs. When the dust-pellet no longer covers the measuring blade, it returns to turn and the relay retunrs to its normal state.

- GRID OF 30X30 for material unloading.

- COLOUR RAL 7001 IN BOTTOM BRACKET. (another colour can be possible too)

- INDUCTIVE DETECTOR.

- HOPPER CONICAL TRUNK OF 400 LITER MODEL Ø700 MM. (another capacity can be possible too).

Source: https://bulkinside.com/efficient-unloading-of-bags-containing-powdered-products/